Roof coating generally requires 4 to 24 hours of drying time before it can withstand rain, depending on the product type and weather conditions. Allowing the coating to dry properly is essential for it to bond securely to the roof surface, cure effectively, and create a durable, waterproof barrier. If exposed to rain too soon, the coating can wash away, blister, or fail prematurely leading to costly repairs or reapplication.

Let's look at how long does roof coating need to dry before rain. This article also covers the importance of drying times, differences between coating types, key factors that affect drying, how to plan around the weather, what to do if rain hits unexpectedly, and why the manufacturer’s data sheet should always guide your process.

Allowing a roof coating to dry properly is one of the most critical steps in ensuring a long-lasting and effective roofing system. Skipping or rushing this stage can compromise the coating’s performance, leading to avoidable damage and costly repairs.

If rain hits before the coating has dried, it can wash away the uncured material, wasting product and leaving your roof unprotected. Ensuring adequate drying time forms a strong barrier against water intrusion.

Drying allows the coating to bond securely to the roof surface. Without proper adhesion, the coating can peel, blister, or separate, shortening its lifespan significantly.

A fully cured coating creates a seamless, watertight layer that shields the roof from leaks. Inadequate drying can cause weak spots where water may seep through.

Proper drying helps prevent unsightly issues like bubbling, streaking, or uneven finishes. This not only maintains the roof's functionality but also its aesthetic value.

Most coating warranties are only valid if the product is applied under recommended conditions, including drying time. Ignoring this step can void coverage and increase long-term risk.

A roof coating that is allowed to dry and cure correctly will generally perform better and last longer. It will be more resistant to UV degradation, thermal expansion, and ponding water. Proper drying ensures that the coating’s protective and reflective properties function as intended for years to come.

When a coating dries properly the first time, it reduces the likelihood of early failures or weak spots that require patching. This means fewer disruptions, lower maintenance costs, and greater confidence in your roofing system.

Taking the time to let your roof coating dry thoroughly is an investment in durability, performance, and peace of mind. It ensures the coating performs as intended and stands up to the elements for years to come.

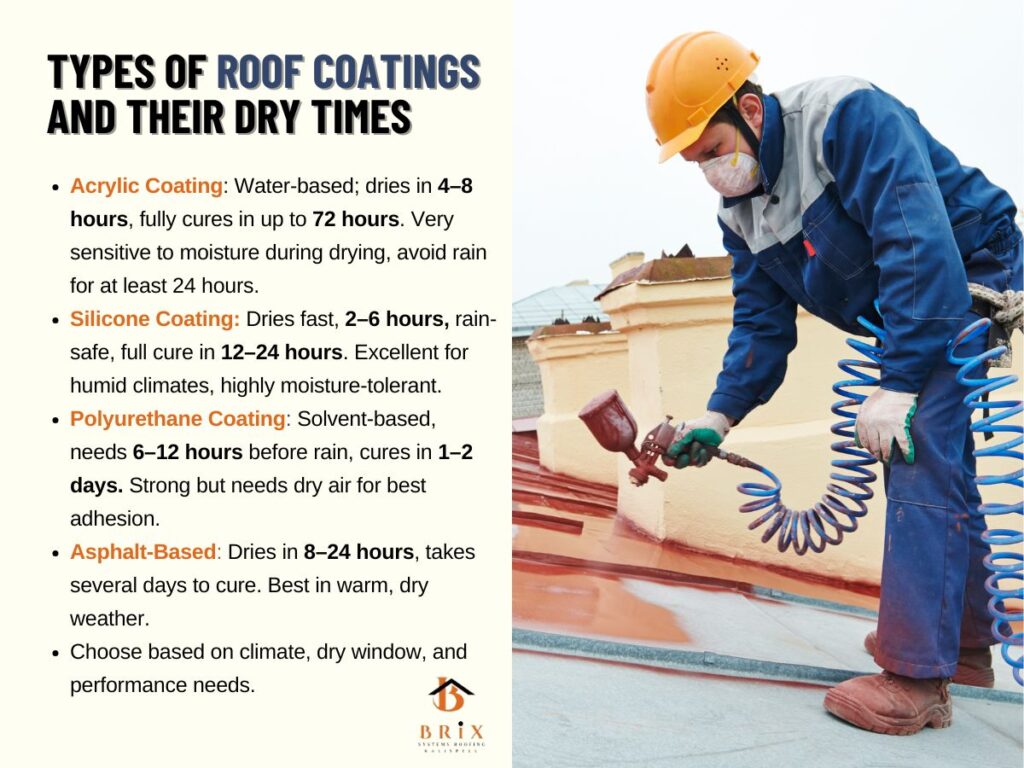

Choosing the right type of roof coating involves more than just picking the most durable or affordable option, it also means understanding how long each type needs to dry before it can resist rain. Drying times vary significantly depending on the coating’s composition, which directly impacts project timing and weather planning.

Acrylic coatings are water-based and typically require 4 to 8 hours to become rain-safe, with full curing taking up to 72 hours. Because they're highly sensitive to moisture during drying, it's best to apply them only when no rain is forecast for at least 24 hours.

Silicone coatings generally become rain-safe within 2 to 6 hours and fully cure in about 12 to 24 hours. They are highly moisture-tolerant, making them ideal for humid or unpredictable climates.

This solvent-based coating needs 6 to 12 hours to dry before it can withstand rain and typically cures fully within 24 to 48 hours. It's known for its toughness and chemical resistance but still requires dry conditions for proper initial adhesion.

Asphalt coatings usually take 8 to 24 hours to dry and may need several days to cure completely. Their drying time is highly dependent on weather conditions, particularly temperature and humidity.

Understanding the specific drying times of each roof coating type helps ensure the best performance and longevity of your application. Always refer to manufacturer guidelines and plan your project around weather conditions to avoid premature rain exposure.

The drying time of roof coatings can vary significantly based on several environmental and application-specific factors. Being aware of these variables is essential for achieving optimal performance and preventing premature coating failure due to unexpected weather changes or improper application.

Warmer temperatures generally accelerate the drying process by enhancing solvent evaporation or curing reactions. Most roof coatings require a minimum ambient temperature of around 50°F (10°C) for proper drying and adhesion.

High humidity slows the evaporation of water in water-based coatings like acrylics, significantly extending drying times. Conversely, some coatings like silicone may cure more reliably even in moist conditions.

Light to moderate airflow can help speed up drying by encouraging evaporation, but strong winds can introduce dust or debris into the coating. Excessive wind may also cause uneven drying, affecting the coating’s finish and adhesion.

Applying a coating too thickly increases drying and curing times, sometimes beyond the expected window for weather safety. It's important to follow the manufacturer's recommended spread rate to ensure consistent performance.

Direct sunlight can accelerate drying by providing heat and UV energy, particularly for UV-reactive coatings like acrylics. Overcast or shaded conditions may slow this process and require longer wait times before the coating is rain-safe.

Controlling and accounting for these key factors ensures that your roof coating cures properly and delivers maximum durability. Always assess site-specific conditions before and during application for the best results.

Successfully applying a roof coating requires careful timing, especially when rain is in the forecast. Planning around the weather ensures that the coating has enough time to dry and cure properly, helping avoid costly rework and premature failure.

Always consult a reliable weather forecast for at least 48 to 72 hours before starting the project. This helps you avoid surprise rain events and ensures you have a clear, dry window for application and curing.

Even if a coating is rain-safe within a few hours, it’s wise to build in at least a 24-hour buffer of dry weather. This extra margin protects against unexpected delays in drying due to humidity, cool temperatures, or over-application.

Start applying the coating in the morning to maximize daylight and warmth, which aid in faster drying. Early application also helps avoid the cooler, damper conditions that typically occur in the late afternoon and evening.

Don’t rely solely on forecasts use a thermometer, hygrometer, and visual checks to assess real-time temperature, humidity, and cloud cover. On-site awareness allows you to make better decisions and adjust your schedule as needed.

Proactive planning and real-time monitoring are key to a successful roof coating job. By accounting for the weather before and during application, you greatly increase the chances of a durable, long-lasting result.

Despite the best planning, sudden rainstorms can sometimes catch you off guard during or shortly after a roof coating application. Knowing how to respond quickly and effectively can help minimize damage and determine whether repairs or reapplication are necessary.

Stay off the roof during and immediately after rain to prevent slipping hazards and avoid disturbing the partially cured coating.

Allow the roof to dry thoroughly before assessing any damage, as inspecting too early can cause further smearing or indentations in the coating.

Look for signs like bubbling, streaking, or areas where the coating has washed off, which may indicate the need for touch-up or full reapplication.

If damage is localized, patch the affected sections once dry. For more extensive issues, a full recoat may be necessary to restore protection.

If you're unsure how to proceed or if the damage is extensive, consult the coating manufacturer for specific guidance to avoid compromising the product warranty.

Acting calmly and deliberately after unexpected rain can help salvage your roof coating project. Quick assessment and informed action are key to reducing long-term impact and ensuring a successful finish.

The most reliable way to ensure proper roof coating application is to follow the manufacturer's data sheet. It contains essential, product-specific details that protect your results and warranty.

In short, always read the data sheet, it’s your go-to resource for getting the job done right.

To simplify planning and product selection, here’s a quick reference chart that summarizes drying times, cure periods, and weather sensitivity for common types of roof coatings. This table can serve as a handy guide when preparing for your next roof coating project.

| Coating Type | Rain-Safe Time | Full Cure Time | Weather Sensitivity | Ideal Conditions |

| Acrylic | 4–8 hours | 24–72 hours | High | Warm, dry, low humidity |

| Silicone | 2–6 hours | 12–24 hours | Low | Tolerates humidity; rain-resistant |

| Polyurethane | 6–12 hours | 24–48 hours | Medium | Dry, well-ventilated conditions |

| Asphalt-Based | 8–24 hours | 1–3 days | High | Warm, dry, stable temperatures |

| Elastomeric (general) | 6–12 hours | 24–48 hours | Medium | Dry days with moderate temps |

This quick chart helps you match your coating type with the proper drying window and environmental conditions. Always cross-check with the product’s data sheet for specific recommendations before application.

The ultimate success and durability of your roof coating project depend entirely on allowing sufficient drying and curing time. Although it might be tempting to speed up the process, patience is crucial for properly protecting your roof. Rushing this critical step can lead to a compromised coating, necessitating costly reapplication and undermining the coating's ability to perform as intended.

To ensure your roof coating performs reliably for years to come, always monitor the weather for dry conditions, understand your specific product’s drying and curing requirements, and closely follow the manufacturer’s instructions. A carefully applied, fully cured coating not only protects your roof but also adds lasting value to your home or building.