Silicone coating is considered the best option for metal roofs because of its exceptional durability, resistance to standing water, and long-lasting UV protection. It offers a reliable, energy-efficient solution that performs well in extreme weather conditions, making it ideal for extending the life of both residential and commercial metal roofs.

This detailed article will delve into the various types of metal roof coatings, their benefits, considerations for selection, and key factors for successful application, helping you make an informed decision for your specific needs.

Coating a metal roof is a critical step in safeguarding its integrity and maximizing its lifespan. While metal roofs are inherently strong and durable, they are still exposed to harsh environmental factors such as moisture, ultraviolet (UV) rays, temperature fluctuations, and physical wear. Applying a high-quality roof coating not only protects the metal from these elements but also enhances its performance, efficiency, and overall appearance.

Metal roofs, especially those in coastal or humid regions, are highly susceptible to rust and corrosion caused by prolonged exposure to moisture and oxygen. Roof coatings create a durable, waterproof barrier that prevents these corrosive elements from reaching the metal surface, thereby preserving structural integrity and preventing costly repairs.

Continuous exposure to the sun’s ultraviolet rays can weaken the metal, leading to fading, chalking, and brittleness over time. Reflective coatings shield the roof by bouncing UV rays away, reducing heat buildup and protecting the metal from premature aging and damage.

Over time, small cracks, seams, or fastener holes may develop in a metal roof, increasing the risk of leaks and water damage. A quality roof coating seals these potential entry points, forming a seamless, flexible waterproof layer that prevents water infiltration and protects the building’s interior.

Metal roofs can absorb significant amounts of heat, which can cause higher indoor temperatures and increased air conditioning costs. Reflective roof coatings minimize heat absorption by reflecting sunlight, which not only cools the building but also reduces energy consumption and utility bills.

By protecting the roof from environmental wear and tear, coatings help slow the natural aging process of metal roofs. This prolongs the functional life of the roof, delays the need for expensive replacements, and maintains the building’s value.

Coatings can revitalize the appearance of an aging metal roof by restoring its color and shine. This improves curb appeal and can even increase property value without the cost of a full roof replacement.

Compared to completely replacing a metal roof, applying a coating is a relatively low-cost maintenance strategy that offers significant returns in terms of durability and energy savings. It helps avoid frequent repairs and reduces long-term operational costs.

Coating a metal roof is a practical and efficient way to protect your investment, enhance energy efficiency, and extend the roof’s useful life. Whether your goal is to prevent corrosion, improve appearance, or lower energy bills, a well-chosen roof coating can deliver lasting benefits and peace of mind.

When it comes to protecting and enhancing a metal roof, choosing the right coating is essential. Different types of coatings offer unique advantages depending on climate, roof conditions, and specific performance needs. Here are the top metal roof coating options to consider:

Acrylic coatings are water-based and known for their excellent reflectivity and UV protection. They’re cost-effective, easy to apply, and ideal for sunny climates, but they may not perform as well in areas with frequent standing water.

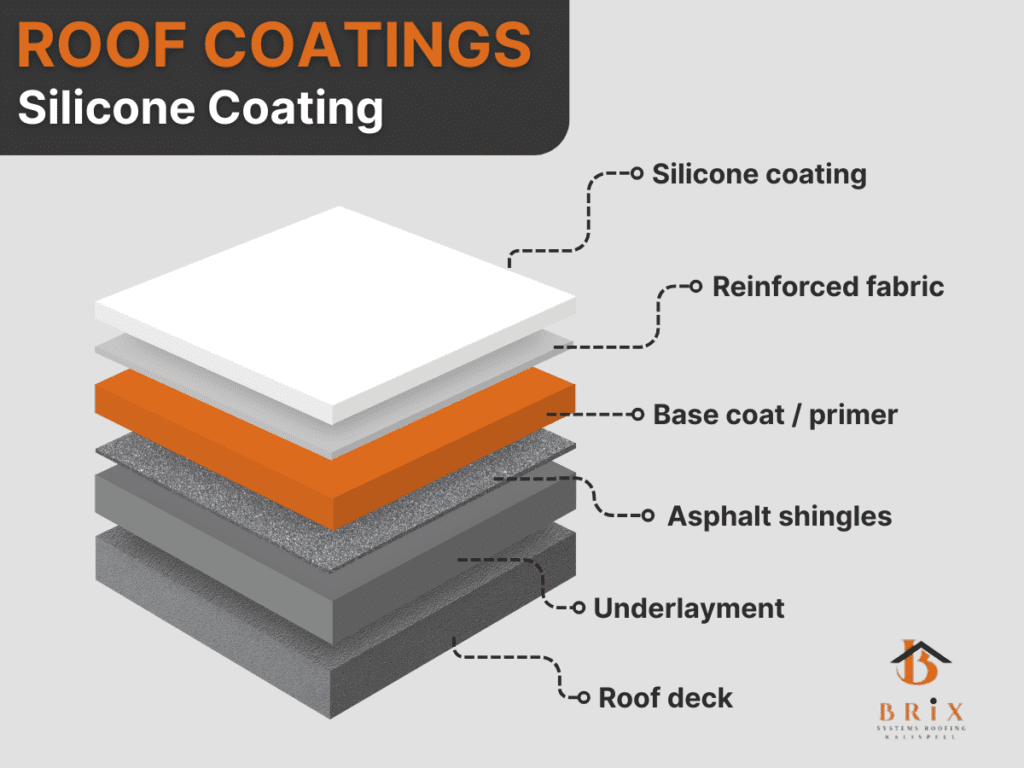

Silicone coatings offer exceptional water resistance, making them ideal for flat or low-slope roofs where water tends to pool. They also provide excellent UV protection and long-term durability, though they can be more expensive and attract dirt over time.

Polyurethane coatings are highly durable and resistant to impact, abrasion, and chemical exposure. They are best suited for industrial or commercial roofs that experience heavy foot traffic or extreme weather conditions.

Asphalt coatings are an affordable option that provides basic waterproofing and protection. While not as reflective or long-lasting as other types, they can be useful for quick fixes or as part of layered systems on older roofs.

Each coating type serves different needs and performs best under specific conditions. Choosing the right one involves balancing your budget, climate, and the demands of your roof to ensure long-term performance and protection.

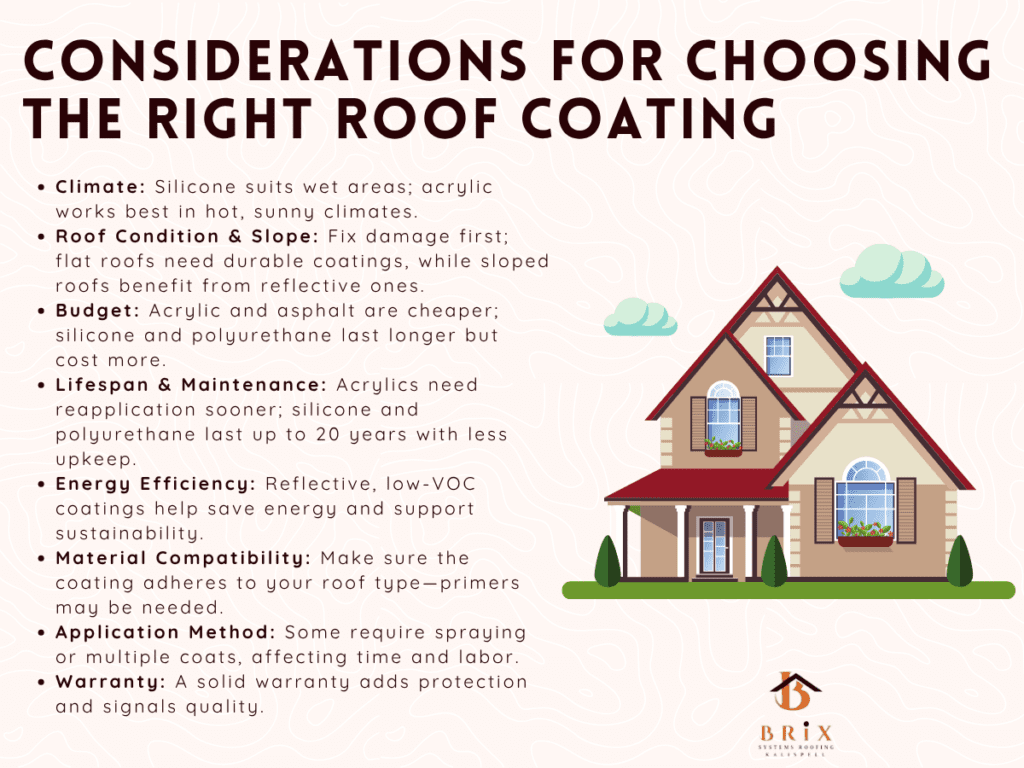

Choosing the right roof coating for a metal roof involves considering several important factors to ensure the best protection and performance. Each coating type responds differently depending on environmental conditions, roof characteristics, and budget. Understanding these factors helps you make an informed decision tailored to your specific needs.

Your local climate dictates how a roof coating performs. Silicone excels in wet areas prone to ponding due to its superior waterproofing. Acrylics are better for hot, dry climates because of their strong UV resistance and reflectivity.

The existing condition of your metal roof affects coating adhesion and performance. Address any rust, corrosion, or damaged panels before coating. For flat roofs, choose durable coatings like silicone or polyurethane that withstand standing water, while steep roofs benefit from lighter, reflective acrylics for energy efficiency.

Cost is a major factor in coating decisions. Acrylic and asphalt coatings are more budget-friendly upfront, ideal for basic protection. Silicone and polyurethane, though pricier initially, offer longer-lasting protection and superior resistance, saving money long-term.

Consider how much upkeep a coating needs and its expected lifespan. Acrylics typically require reapplication every 5-10 years. Silicone and polyurethane last 10-20 years with less maintenance, making them more cost-effective over time if you want to reduce effort.

Reflective coatings reduce energy consumption by lowering roof temperatures. For sustainability, choose low-VOC options like many acrylic and silicone coatings, which also contribute to green building certifications.

Ensure your chosen coating properly adheres to your specific metal roof or existing layers. Verify compatibility with materials like galvanized steel or aluminum. Some coatings may also need a primer for better bonding, especially on older or previously coated roofs.

Different coatings require varied application techniques, such as spraying, rolling, or brushing. Some products need multiple coats or specialized equipment, impacting labor and project time. Understand these requirements to decide on professional help versus a DIY approach.

A reputable manufacturer's warranty protects your investment. Review terms for coverage length and maintenance requirements. Strong manufacturer support often indicates a higher quality and more reliable coating.

Choosing the best roof coating involves a careful evaluation of environmental factors, roof specifics, budget, and long-term goals. By considering climate, roof condition, costs, maintenance needs, and sustainability, you can select a coating that delivers optimal protection, performance, and value for your metal roof.

When deciding to coat a metal roof, one major consideration is whether to hire a professional or take the DIY route. Both options have their pros and cons, depending on the complexity of the job, your experience level, and the type of coating being used.

Hiring a professional ensures that the roof is properly cleaned, prepped, and coated according to manufacturer specifications. This often leads to better adhesion, longer-lasting results, and may come with a warranty that protects your investment.

For those with roofing experience or smaller, simpler roofs, applying a coating yourself can be a cost-saving option. However, mistakes in surface preparation, coating thickness, or weather timing can lead to reduced performance or premature failure.

Ultimately, the choice between professional and DIY application depends on your confidence, the roof’s condition, and the type of coating selected. While DIY may be more affordable upfront, professional installation often provides greater reliability and long-term value.

Applying a coating to a metal roof involves more than just rolling on a product—it requires proper planning, surface preparation, and attention to detail to ensure long-lasting results. Following the correct steps can maximize the performance of the coating and extend the life of the roof significantly.

The roof surface must be cleaned thoroughly to remove dirt, rust, old coatings, and other debris. Pressure washing is often used to ensure a clean surface that allows the new coating to adhere properly.

Any damaged areas, such as holes, cracks, or loose fasteners, should be repaired before applying the coating. This helps create a smooth, even surface and prevents future leaks from forming underneath the coating.

Some coatings require a primer to improve adhesion, especially on older or bare metal roofs. Choosing the right primer ensures a stronger bond between the roof and the coating, leading to better durability.

Apply the coating according to the manufacturer's specifications, including recommended thickness and curing time. Using the correct tools—such as sprayers, rollers, or brushes—helps achieve a uniform layer across the entire roof.

Coating should be applied in favorable weather conditions—typically dry, mild days without rain in the forecast. Temperature and humidity affect how the coating cures, so choosing the right timing is critical to success.

A successful metal roof coating job depends on careful preparation, the right materials, and proper application techniques. By following these key steps, you can ensure a longer-lasting, more effective roof coating that protects your investment for years to come.

The best coating for your metal roof is silicone, thanks to its excellent waterproofing, UV resistance, and durability—especially in areas with standing water or harsh weather. While other options like acrylic or polyurethane may suit specific needs, silicone provides the most reliable, long-lasting protection.

Choosing the right coating depends on your climate, roof condition, budget, and maintenance needs. By considering these factors and applying the coating properly, you can extend your roof’s life, improve energy efficiency, and save on future repairs.